Direct Drive motors

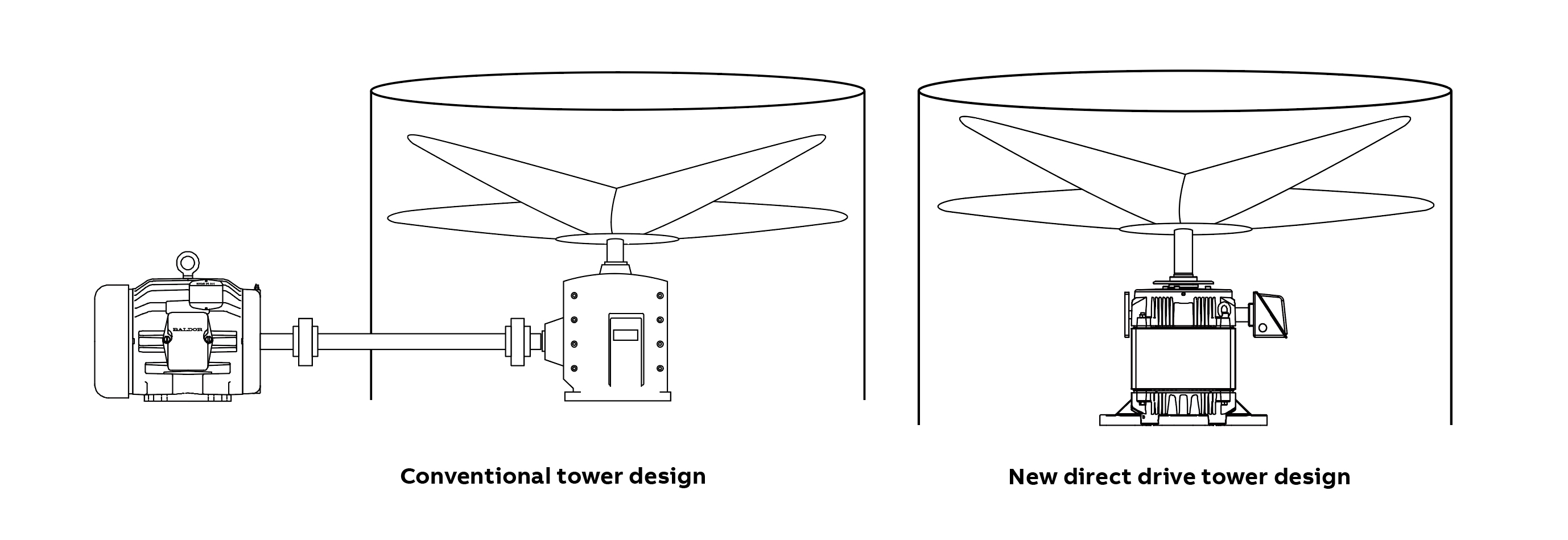

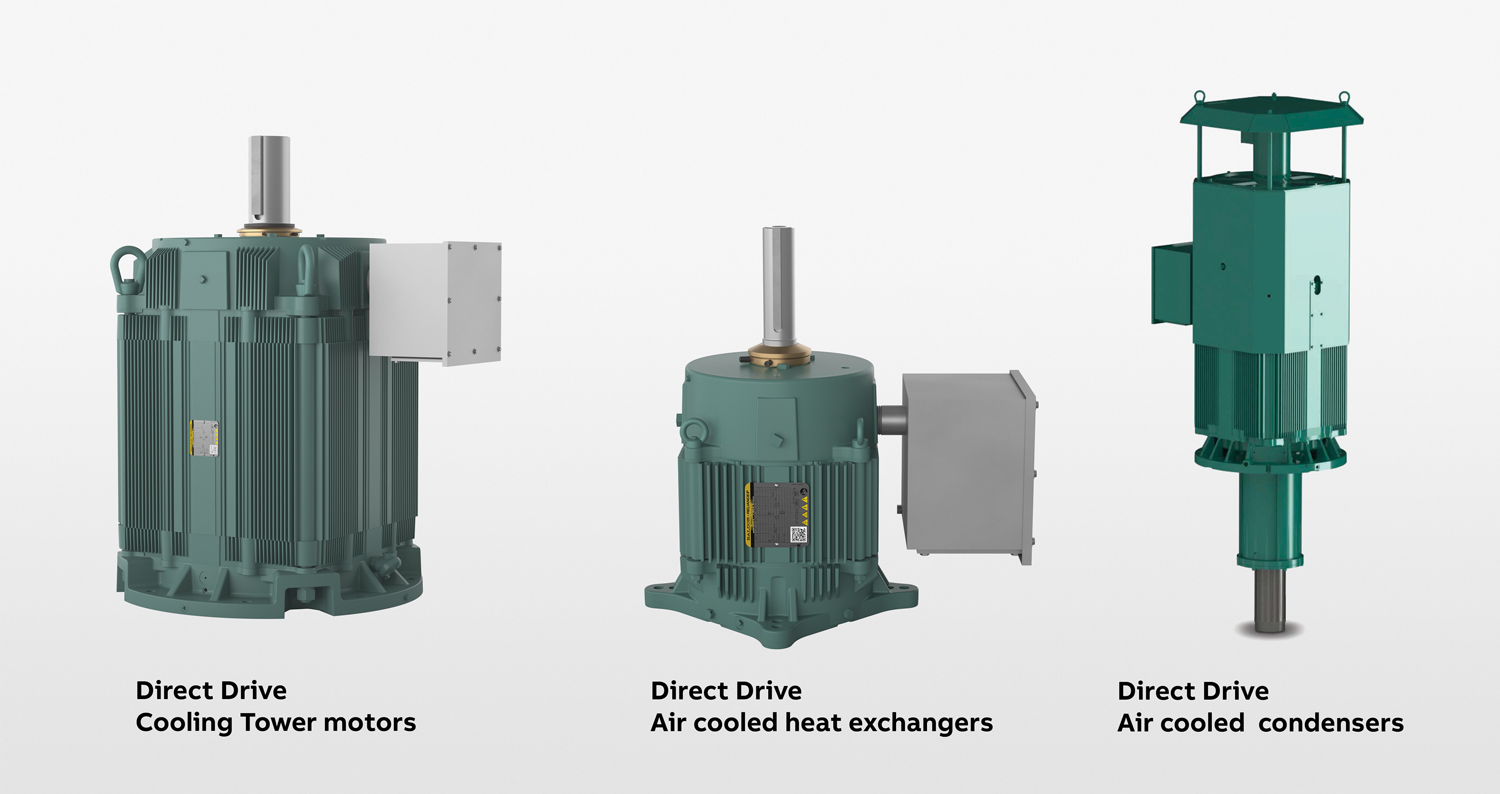

The Baldor-Reliance direct drive motors are synchronous PM motors that use laminated finned frame construction to provide a highly efficient power dense package with flange mounting dimensions that can replace the right angle gearbox and jack shaft installation in many conventional cooling towers. This same technology is offered in conventional, yet power dense, foot mounted designs that can replace the belt and sheave application where more vertical mounting space is available. Derived from one of the toughest motor platforms used in the most demanding industrial applications, Baldor-Reliance direct drive motors are the right solution for operation inside the tower’s hot and humid environment. Direct drives are ideal for cooling towers, air cooled condensers and air cooled heat exchangers.

Cooling Tower Features

- Increased efficiency and power factor performance

- Operates at optimal system efficiency point with variable speed control

- Increased system reliability with fewer mechanical parts

- Simplified installation or retrofit with gearbox foot print

- Inpro/Seal® combination slinger and labyrinth non-contact shaft seal protects motor from water ingress and contamination

- Easy to use drive control parameters

- Interfaces easily to building automation control systems

- Replaces high maintenance conventional gear and belt drive arrangements

- Quieter operation than conventional motor/gearbox system

Common industries

- HVAC

- Chemical, oil and gas

- Power generation

Common applications

- Wet and dry cooling towers

- Air cooled condensors

- Air cooled heat exchangers

Related videos

Cooling Tower Wizard Software

Please completely fill out the form below in order to receive the Cooling Tower Wizard Software 3.2.0.178 via email.