Pulp and Paper

Industry Overview

Now more than ever, it is vital that pulp and paper companies choose supplier partners that understand their processes and offer a full range of solutions.

At ABB, we understand that all electric motors and variable frequency drive products must perform reliably - at maximum efficiency - around the clock. We not only supply these products, but also work with customers to improve plant reliability and achieve sustainability goals in order for them to remain competitive and profitable.

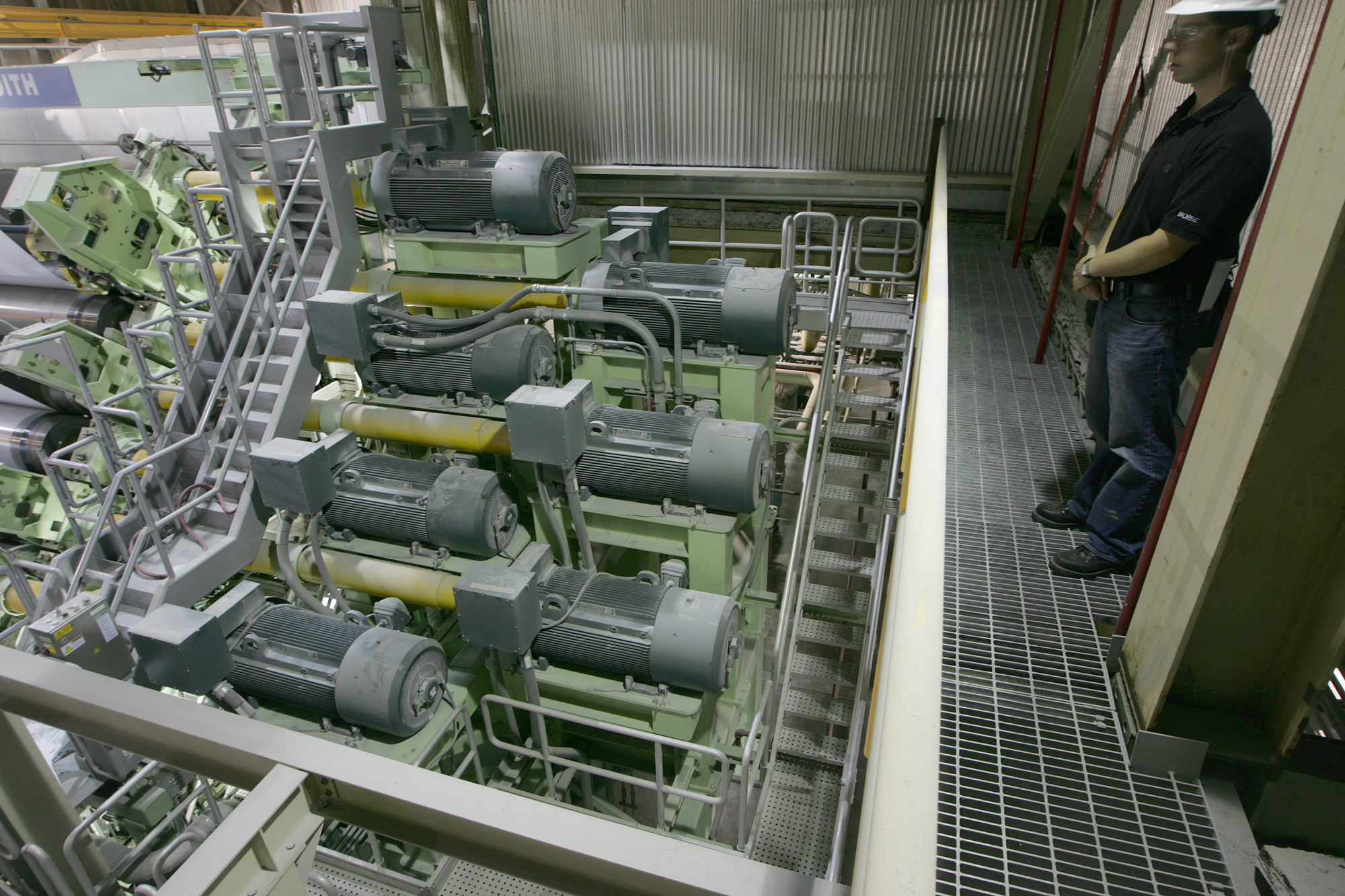

Baldor-Reliance products are at work in environmental conditions that include everything from wind, dust and snow to extreme temperatures including tropical. Wherever the application, our extensive stock product lines are backed up by many years in custom-engineered solutions. This kind of flexibility allows us to meet the individual needs of any pulp and paper application, anytime... anywhere.

Expertise and wide product portfolio

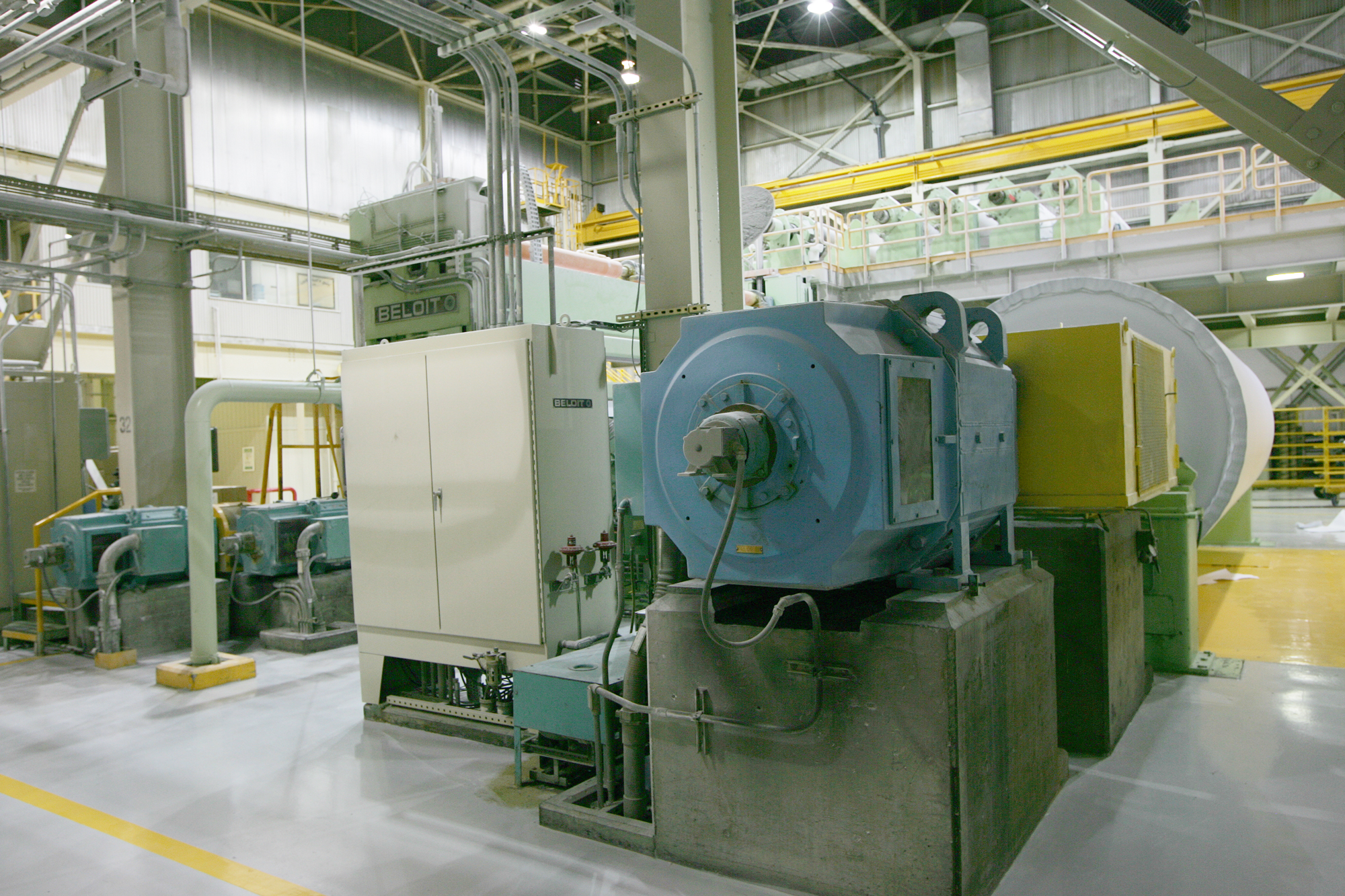

Many pulp and paper mills have been in operation for a long time - and modern motors offer a lot of benefits in terms of process improvements, energy savings and reduced maintenance costs. Converting older DC motors to AC motors is made easy with Baldor-Reliance motors since we design conversions and upgrades with the installed base in mind. With over 100 years of experience, we will support your transition to select the right solutions and maximize mill performance and reliability.

Operational uptime

Energy efficiency and sustainability

Associated Products

Common applications

- Cranes

- Conveyor

- Debarker

- Chipper/cutter

- Fans

- Pumps

- Presses

- Dryers

- Winders

- Calendars

- Packaging

Vertical segments

- Wood handling

- Pulping

- Printing and paper making

- Recycling