Nouvelles de la société

Toutes les Actualités

2023-07-20 Company News

To summarize the outcome in the second quarter, I would first highlight the 2% comparable order growth which was up from last year's already high level, and the positive book-to-bill. It was good to see that the customer activity remained robust throughout the period. Secondly, the high revenue growth of 13% (17% comparable) supported by backlog execution. Thirdly, the record-high achievements on both absolute Operational EBITA of $1.4 billion and Operational EBITA margin of 17.5%, up 200 basis points from last year, with all four business areas above 15%. This was supported by a strong price contribution which more than offset labor inflation as well as some limited cost inflation related to commodities, with additional support from operational leverage on increased volumes in production. And lastly, the solid cash flow from operating activities of $760 million. All the while we executed on portfolio optimization and continued to introduce leading new technology to help our customers become more sustainable and resource efficient. In my view, the quarter is an additional indication that we are establishing ABB's operational performance at a higher level.

2023-05-16 Company News

The Northwest Passage is the sea route between the Atlantic and Pacific oceans through the Arctic Ocean, along the northern coast of North America. This 6,000-kilometer stretch of treacherous waters is considered one of the most dangerous nautical routes in the world. For centuries, explorers sought a navigable passage as a possible trade route to Asia but were blocked by North, Central, and South America; however, in 1906, a team of Norwegian sailors successfully traversed the passage. Since then, specialty vessels with crews of dozens, if not hundreds, of highly trained sailors have attempted the voyage; some emerged successfully on the other side, but just as many were forced to turn back, call for rescue – or worse.

2023-05-03 Company News

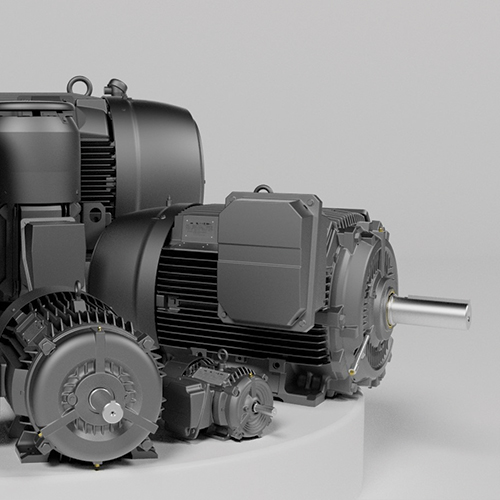

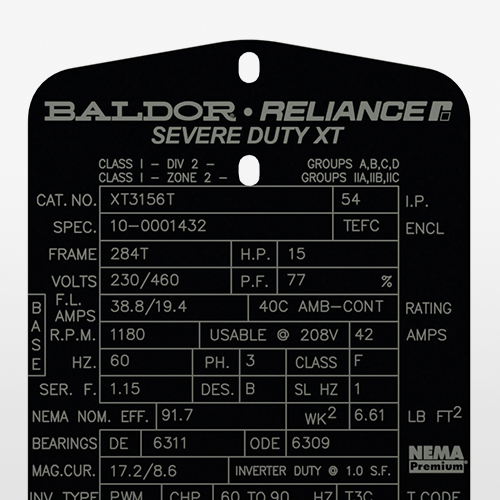

ABB announced today it has completed its acquisition of the Siemens low voltage NEMA motor business. The transaction was originally announced August 11, 2022, and financial terms of the transaction were not disclosed. The business employs around 600 people and generated revenues of approximately $63 million in 2021.

2023-05-03 Company News

ABB announced today at the SelectUSA Investment Summit that it is investing $1 million in the University of Arkansas - Fort Smith (UAFS) to help position the school to become one of the nation’s leading advanced manufacturing educational institutions. This announcement follows ABB’s recent commitment to invest $170 million in manufacturing and distribution operations in 2023.

2023-04-25 Company News

2023-04-06 Company News

Soler & Palau, or S&P, was founded in 1951 in Ripoll, Spain, near Barcelona, and has grown to six development centers and 25 factories worldwide. S&P is a fan manufacturer and partners with air-handling OEMs to allow customers to buy complete systems. Soler & Palau Mexico, located in Puebla, about 100km (60 miles) southeast of Mexico City, has been an ABB customer for three years. ABB’s Baldor-Reliance EC Titanium integrated motor-drive systems and inverter duty HVAC motors power many of S&P’s air-handling units. These units help address air quality and health needs by increasing filtration in indoor environments in residential and commercial buildings. OEMs demand high performance from S&P, and S&P demands high performance from its motors. ABB’s ability to meet these needs, coupled with the company’s commitment to corporate values and customer service, played a vital part in S&P choosing ABB motors.

2023-04-05 Company News

ABB is accelerating its growth strategy in the United States by investing approximately $170 million and creating highly skilled jobs in manufacturing, innovation and distribution operations. ABB is committed to growing in the US by investing in its electrification and automation businesses that meet increased demand from industry-leading customers, while supporting the clean energy transition and the trend towards reshoring of production. This commitment is highlighted by today’s pouring of the concrete foundations for a greenfield drives and services facility in New Berlin, Wisconsin. The US is ABB’s largest market, comprising 24 percent of the company’s annual revenue.

2023-04-04 Company News

ABB, a global leader in technology innovation, is celebrating the “floor pour” of its newest U.S. flagship campus at 18250 W. Lincoln Avenue. The Greenfield location in New Berlin will serve as the U.S. headquarters, manufacturing facility and distribution center for the Drives and Motion Services businesses. The new facility is anticipated to open in late 2024 and will accommodate 720 ABB employees. Approximately $100 million is being invested in the project and is expected to create 100 new jobs over the next three years.

2023-03-23 Company News

2023-03-07 Industry News

Commercial marine motors in general are high-grade motors treated for corrosion resistance and designed for use on shipboard applications. These motors meet the regulatory requirements governed by three major specifications: the American Bureau of Shipping (ABS) Rules for Building and Classing Marine Vessels1, the United States Coast Guard (USCG) Electrical Engineering Regulations2 and the Institute of Electrical and Electronics Engineers (IEEE) Standard 45, Recommended Practice for Electric Installations on Shipboard3. Marine motors are also used for other-than-shipboard service in functions on offshore drilling rigs, shipyard applications and port equipment. Marine motors are usually mounted to steel structures, which are subject to vibration and shock or pitch and roll movement, and typical marine application settings are very humid and salt-laden harsh environments. Therefore, the environments in which shipboard motors operate and the functions they perform require unique design and construction considerations above those of standard industrial motors.

Nouvelles de la société

2023-07-20 Company News

To summarize the outcome in the second quarter, I would first highlight the 2% comparable order growth which was up from last year's already high level, and the positive book-to-bill. It was good to see that the customer activity remained robust throughout the period. Secondly, the high revenue growth of 13% (17% comparable) supported by backlog execution. Thirdly, the record-high achievements on both absolute Operational EBITA of $1.4 billion and Operational EBITA margin of 17.5%, up 200 basis points from last year, with all four business areas above 15%. This was supported by a strong price contribution which more than offset labor inflation as well as some limited cost inflation related to commodities, with additional support from operational leverage on increased volumes in production. And lastly, the solid cash flow from operating activities of $760 million. All the while we executed on portfolio optimization and continued to introduce leading new technology to help our customers become more sustainable and resource efficient. In my view, the quarter is an additional indication that we are establishing ABB's operational performance at a higher level.

2023-05-16 Company News

The Northwest Passage is the sea route between the Atlantic and Pacific oceans through the Arctic Ocean, along the northern coast of North America. This 6,000-kilometer stretch of treacherous waters is considered one of the most dangerous nautical routes in the world. For centuries, explorers sought a navigable passage as a possible trade route to Asia but were blocked by North, Central, and South America; however, in 1906, a team of Norwegian sailors successfully traversed the passage. Since then, specialty vessels with crews of dozens, if not hundreds, of highly trained sailors have attempted the voyage; some emerged successfully on the other side, but just as many were forced to turn back, call for rescue – or worse.

2023-05-03 Company News

ABB announced today it has completed its acquisition of the Siemens low voltage NEMA motor business. The transaction was originally announced August 11, 2022, and financial terms of the transaction were not disclosed. The business employs around 600 people and generated revenues of approximately $63 million in 2021.

2023-05-03 Company News

ABB announced today at the SelectUSA Investment Summit that it is investing $1 million in the University of Arkansas - Fort Smith (UAFS) to help position the school to become one of the nation’s leading advanced manufacturing educational institutions. This announcement follows ABB’s recent commitment to invest $170 million in manufacturing and distribution operations in 2023.

2023-04-25 Company News

2023-04-06 Company News

Soler & Palau, or S&P, was founded in 1951 in Ripoll, Spain, near Barcelona, and has grown to six development centers and 25 factories worldwide. S&P is a fan manufacturer and partners with air-handling OEMs to allow customers to buy complete systems. Soler & Palau Mexico, located in Puebla, about 100km (60 miles) southeast of Mexico City, has been an ABB customer for three years. ABB’s Baldor-Reliance EC Titanium integrated motor-drive systems and inverter duty HVAC motors power many of S&P’s air-handling units. These units help address air quality and health needs by increasing filtration in indoor environments in residential and commercial buildings. OEMs demand high performance from S&P, and S&P demands high performance from its motors. ABB’s ability to meet these needs, coupled with the company’s commitment to corporate values and customer service, played a vital part in S&P choosing ABB motors.

2023-04-05 Company News

ABB is accelerating its growth strategy in the United States by investing approximately $170 million and creating highly skilled jobs in manufacturing, innovation and distribution operations. ABB is committed to growing in the US by investing in its electrification and automation businesses that meet increased demand from industry-leading customers, while supporting the clean energy transition and the trend towards reshoring of production. This commitment is highlighted by today’s pouring of the concrete foundations for a greenfield drives and services facility in New Berlin, Wisconsin. The US is ABB’s largest market, comprising 24 percent of the company’s annual revenue.

2023-04-04 Company News

ABB, a global leader in technology innovation, is celebrating the “floor pour” of its newest U.S. flagship campus at 18250 W. Lincoln Avenue. The Greenfield location in New Berlin will serve as the U.S. headquarters, manufacturing facility and distribution center for the Drives and Motion Services businesses. The new facility is anticipated to open in late 2024 and will accommodate 720 ABB employees. Approximately $100 million is being invested in the project and is expected to create 100 new jobs over the next three years.

2023-03-23 Company News

2023-03-06 Company News

AGronomic IQ needed a quick turnaround on delivering HVAC units to customers expanding their cannabis growing facility. So, when post-pandemic supply chain challenges hit their foreign drive supplier, they pivoted to find an energy-efficient, applicable no-change solution. ABB answered the call with Baldor-Reliance® EC Titanium™ motors, delivering high energy efficiency, cost-efficiency, reliability, and support above and beyond expectations.

Nouveaux produits

2023-03-06 New Products

ABB has added IEC frame options to its integrated motor-drive offering of Baldor-Reliance EC Titanium motors. Standard features include aluminum housed top-mount of axial mount integrated drive, IP55 enclosure, internal shaft grounding brush and class-F insulation. EC Titanium motors are rated for inverter use per IEC 60034-18-41. The IEC integrated motor-drive is capable of operating as a top-mount drive in ratings of 1 to 10 HP (0.75 – 7.5 kW), or axial-mount drive in ratings 1 to 7.5 HP (0.75 – 5.5 kW).

2022-01-31 New Products

ABB announces the Baldor-Reliance® Critical Cooling motor with sealed hybrid ceramic bearings offering the highest level of protection and performance when used with variable frequency drives (VFDs) controlled motors. These innovative motors are able to operate at the high temperatures, partial speeds and demanding loads required in critical cooling applications.

2021-10-26 New Products

2021-05-14 New Products

2020-10-07 New Products

2020-08-03 New Products

Globally, demand for electricity will grow faster than for any other form of final energy. Thus, emissions will keep rising, unless we start doing something different. This global electricity demand growth is expected to double by 2040. With electric motors consuming an estimated 1/3 of the world’s electricity… that number is expected to be the equivalent to adding an electricity market the size of China.

2020-05-26 New Products

2020-01-28 New Products

Motor standards have been in place for decades, yet there is a growing demand to achieve greater efficiencies as regulations continue to tighten on the total system for fans, pumps and compressors. Equipment manufacturers are turning to new motor technologies to achieve the highest system efficiency possible from wire to air while using sustainable materials.

2019-10-31 New Products

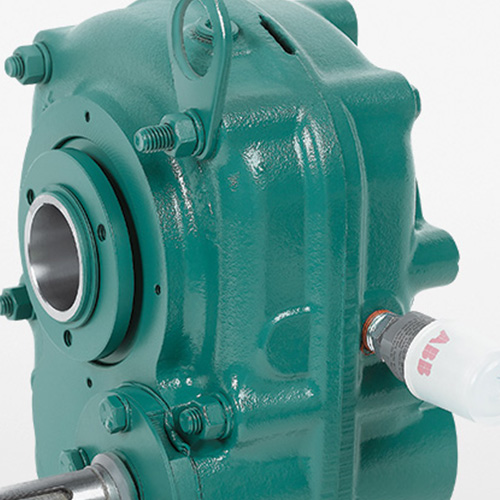

The ABB Ability™ Digital Powertrain concept has now been extended to cover Dodge gear reducers fitted with the smart sensor for mechanical products. The Digital Powertrain enables real-time health monitoring of all the critical elements in industrial processes, such as drives, motors, pumps, bearings and gearing. Immediate access to this key data enables operators to maintain optimal conditions for maximum productivity and safety.

2019-07-18 New Products

The AXR 5000 and 5800 Large AC NEMA motors deliver an average of 15 percent more power over conventional designs. They also meet American Petroleum Institute 541 and 547 standards for motors operating in the oil and gas industry.

ABB’s AXR 5000 and 5800 motors offer more HP (horse power) per pound than conventional TEFC (totally enclosed fan cooled) motors but with a smaller frame size in some power ratings. This helps save space, up to 8 inches in overall length in some cases, which enables more compact installations on oil platforms and in refineries.

Prix et distinctions

2022-03-16 Awards & Recognition

The results are in! Once again, ABB and Baldor-Reliance motors have been recognized as most preferred in the category of Electric Motor technology in the 30th annual Reader’s Choice Awards balloting for Control Design Magazine. The readers who responded anonymously to the survey represented diverse process industries with the majority of responses from North America.

2021-06-28 Awards & Recognition

2021-05-28 Awards & Recognition

If there were ever a year when we could all use some good news, it's this one. And this roster of Readers' Choice Awards winners is full of great solutions from solid manufacturers. After months and months of sheltering in place and social distancing and videoconferencing, we've witnessed remote connectivity, artificial intelligence, machine learning and autonomous mobile robots transforming from science fiction into permanent components of the industrial-manufacturing landscape. This year we saw small change in the companies' components and devices preferred by our readers.

2021-03-02 Awards & Recognition

2020-12-08 Awards & Recognition

Consulting-Specifying Engineer magazine has named ABB’s Baldor-Reliance EC Titanium motors a Silver Award winner in the HVAC/R Systems & Equipment category in this year’s Product of the Year contest. The Product of the Year contest is the premier award for new products in the HVAC, fire/life safety, electrical and plumbing systems engineering markets. The annual reader-choice program was created to provide Consulting-Specifying Engineer’s audience with information about the top new products in their fields.

2020-08-21 Awards & Recognition

ABB is pleased to announce its gear plant in Belton, South Carolina has been recognized by the State of South Carolina as a 2020 Safety Award Recipients. This annual recognition allows the State to highlight employers in the state, both large and small, and the success of their safety and health programs.

2020-06-01 Awards & Recognition

This year marks the 20th anniversary of the Control Design Readers’ Choice Awards. The past two decades have been as liberating as they’ve been innovative. Remote capabilities and software-driven enhancements have pushed technology forward so fast there seems to be no limit to what can’t be automated or upgraded. The impossible has become the standard, and industry has shaken off technological restrictions without looking back. When is the last time you even heard someone utter the word, “bandwidth”?

2019-07-30 Awards & Recognition

In the 2019 Control Design Magazine readers choice awards, industry trends and innovations have crept into the rankings. However, many engineers and voters remain grounded and stick with what works for them. For the 17th year in a row, has chosen ABB has the preferred motor supplier in the industrial electrical motor category.

2019-03-29 Awards & Recognition

Readers of Control Magazine have named ABB as the top supplier to deliver the “best technology” in the category of electric motors for 2019. This marks the 7th year in a row that ABB has topped the charts in this survey. In this year’s edition, Control Magazine recognized the full integration of Baldor Electric into ABB which strengthened our top spot.

2018-07-25 Awards & Recognition

ABB, a motor and generator manufacturer, developed an impressive recycling program over the past year. Recycling included more than 2,727 tons of scrap metal, wood, used oil, batteries, electronics, lamps, paper, cardboard and plastic. Other non-recyclable waste was turned into energy through their recent Zero Landfill Initiative. The facility worked with their largest supplier to establish a returnable packaging agreement. In 2017, ABB earned more than $265,000 from the sale of its recyclables. When meals were catered to the facility, excess food was donated to the local fire department. To encourage recycling and zero waste, every employee was trained and these initiatives were incorporated into new employee orientation. ABB also participated in the Upstate Lean Alliance, sharing ideas with and mentoring other businesses.

Nouvelles de l'industrie

2023-03-07 Industry News

Commercial marine motors in general are high-grade motors treated for corrosion resistance and designed for use on shipboard applications. These motors meet the regulatory requirements governed by three major specifications: the American Bureau of Shipping (ABS) Rules for Building and Classing Marine Vessels1, the United States Coast Guard (USCG) Electrical Engineering Regulations2 and the Institute of Electrical and Electronics Engineers (IEEE) Standard 45, Recommended Practice for Electric Installations on Shipboard3. Marine motors are also used for other-than-shipboard service in functions on offshore drilling rigs, shipyard applications and port equipment. Marine motors are usually mounted to steel structures, which are subject to vibration and shock or pitch and roll movement, and typical marine application settings are very humid and salt-laden harsh environments. Therefore, the environments in which shipboard motors operate and the functions they perform require unique design and construction considerations above those of standard industrial motors.

2023-02-20 Industry News

When shopping for a refrigerator, air conditioner or other appliance, most consumers understand the meaning of the government-backed Energy Star rating, sort of like they do the MPG rating on a vehicle. And they can do the math: a dryer with a 95 rating uses less energy than a dryer with an 87 rating. But does it really?

2022-07-18 Industry News

The pandemic has accelerated already-existing transformations within manufacturing, particularly the need for greater digitalisation. It’s also highlighted manufacturing’s economic importance. According to the National Association of Manufacturers (NAM), the sector contributes $2.71 trillion to the economy every year, making US manufacturing equivalent in value to the world’s eighth-largest economy.

2022-05-19 Industry News

2021-10-19 Industry News

Most readers of Plant Engineering magazine are familiar with electric motors made to National Electrical Manufacturers Association (NEMA) standards as commonly used in the U.S., Canada, Mexico, some parts of South America and Saudi Arabia. But nearly 70% of the industrial motors sold worldwide are made to International Electrotechnical Commission (IEC) standards. Motor standards for these motors are MG 1 for NEMA and the 60034 series and 60071 for IEC that define mechanical, electrical, and performance specifications.

2021-10-19 Industry News

Pumps are literally the heart of a food plant, moving vital fluids around. And as with human hearts, electronic monitoring of their condition can ensure continued health. Digital technology has enhanced the performance and the maintenance of many kinds of industrial equipment, and pumps are no exception. The right kind of monitoring and control of pumps, and of the motors and drives that power them, can go a long way toward improving their performance and making sure they keep running.

2021-07-26 Industry News

The motor industry in North America has worked on a standardized basis since the early part of the 20th century. In 1926, the National Electrical Manufacturers Association (NEMA) was established to provide a forum for the standardization of electrical equipment, enabling consumers to select from a range of safe, effective and compatible electrical products. To this day, NEMA updates and publishes standards, application guides and technical papers for electrical products and works in advocacy for the industry.

2021-07-16 Industry News

According to the U.S. Centers for Disease Control and Prevention (CDC), 48 million people get sick, 128,000 are hospitalized and 3,000 die from diseases transmitted by contaminated food annually in the United States. Among the major bacteria that cause these diseases are Listeria and Salmonella. This statistic is alarming and shows that much remains to be done to ensure food safety and public health, especially now that, due to a pandemic like the Coronavirus, hygiene and sanitation requirements have become and will become more rigorous. For this reason, ABB, a world leader in industrial automation with more than one million washdown electric motors installed in the food industry worldwide, continues to design technologies that contribute to energy sustainability, food safety and comply with regulations set by bodies such as the U.S. Department of Agriculture (USDA) and the Food and Drug Administration (FDA). ABB is also known for listening to food processors and organizations such as the U.S. National Sanitation Foundation (NSF) to design products that contribute to the processing of high-quality food products.

2021-07-16 Industry News

2021-04-19 Industry News

To choose the right motor for your application, you need to consider more than just horsepower, speed, and torque, of course. With electric motor systems accounting for about 70% of the electricity demand in industry, energy efficiency has long been a prerequisite that seemed, however, to be reaching its limits. Efficiency is being pushed further through full system optimization, but requirements are also increasing for improved hygiene, safety, connectivity, data availability…everything that will keep those motors and drives—and all the production equipment they keep in motion—from shutting down unexpectedly.